|

01

|

02

|

03

|

04

|

05

|

06

|

07

|

08

|

09

|

10

|

11

|

12

|

13

|

14

|

15

|

16

|

17

|

18

|

|

CG

|

T3

|

/

|

/

|

/

|

Z

|

3X

|

*

|

|

01

|

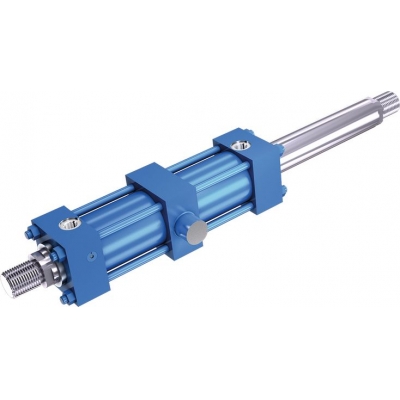

Double-acting cylinder10)

|

CG

|

|

|

02

|

Series

|

T3

|

|

|

Types of mounting

|

|||

|

03

|

Types of mounting DIN/ISO

|

Rectangular flange at cylinder head

|

ME5

|

|

Foot mounting

|

MS2

|

||

|

Trunnion in center

|

MT41)

|

||

|

Types of mounting ISO

|

Trunnion at cylinder head

|

MT1

|

|

|

Extended tie rod, on both sides

|

MX1

|

||

|

Extended tie rod at cylinder head

|

MX3

|

||

|

Tapped hole at cylinder head

|

MX5

|

||

|

04

|

Piston Ø (ØAL) 25 … 200 mm

|

...

|

|

|

05

|

Piston rod Ø (ØMM) 12 … 140 mm13)

|

...

|

|

|

06

|

Stroke length in mm14)

|

...

|

|

|

Design principle

|

|||

|

07

|

Cylinder head and cylinder base connected by tie rod

|

Z

|

|

|

08

|

Component series 30 ... 39 (30 ... 39: unchanged installation and connection dimensions)

|

3X

|

|

|

Line connection / version

|

|||

|

09

|

Pipe thread according to ISO 1179-1

|

B

|

|

|

Metric ISO thread (ISO 6149-1)

|

R17)

|

||

|

Enlarged pipe thread (ISO 1179-1)

|

S

|

||

|

Line connection/position at cylinder head

|

|||

|

10

|

View to piston rod

|

|

1

|

|

2

|

|||

|

3

|

|||

|

4

|

|||

|

Line connection/position at cylinder base

|

|||

|

11

|

View to piston rod

|

|

1

|

|

2

|

|||

|

3

|

|||

|

4

|

|||

|

Piston rod design

|

|||

|

12

|

Hardened and hard chromium-plated

|

H

|

|

|

Piston rod end

|

|||

|

13

|

Thread (DIN/ISO) for swivel head CGKA

|

H

|

|

|

Thread (ISO) for swivel head CGKA

|

D

|

||

|

Internal thread

|

E12)

|

||

|

With mounted swivel head CGKA (DIN/ISO)

|

F5)

|

||

|

With mounted swivel head CGKA (ISO)

|

K5)

|

||

|

End position cushioning

|

|||

|

14

|

Without end position cushioning

|

U

|

|

|

Both sides, self-adjusting

|

D

|

||

|

Both sides, adjustable

|

E4)

|

||

|

Seal design

|

|||

|

15

|

Standard seal system

|

M

|

|

|

Servo quality/reduced friction

|

T

|

||

|

High temperature with reduced friction

|

S

|

||

|

Option 1

|

|||

|

16

|

Without option

|

W

|

|

|

Leakage oil connection

|

B3; 4; 16)

|

||

|

Threaded coupling, on both sides

|

A

|

||

|

Option 2

|

|||

|

17

|

Without option

|

W

|

|

|

Piston rod extension “LY”, specify in mm in plain text

|

Y

|

||

|

18

|

Further details in the plain text

|

...

|

|

| 1) | Trunnion position freely selectable. When ordering, always specify the dimensions “XV” in mm in the plain text |

| 3) | Not possible with type of mounting MS2 and piston Ø 25 mm and end position cushioning “E” |

| 4) | With piston Ø 25 … 100 mm: only line connection “B” possible. With piston Ø 125 … 200 mm: only DIN types of mounting and line connection “B” possible. |

| 5) | Not possible with type of mounting MX1 and MX3 |

| 10) | Not standardized |

| 12) | See dimensions - Piston rod end E (Only possible with standardized piston rod Ø 18 … 140 mm, observe max. operating pressure. |

| 14) | For max. available stroke length, see technical data, and for admissible stroke length (according to the kinking calculation), see project planning information. |

| 16) | Not possible with MT1 |

| 17) | For type of mounting ME5 and ME6, only position 1 and 3 possible |